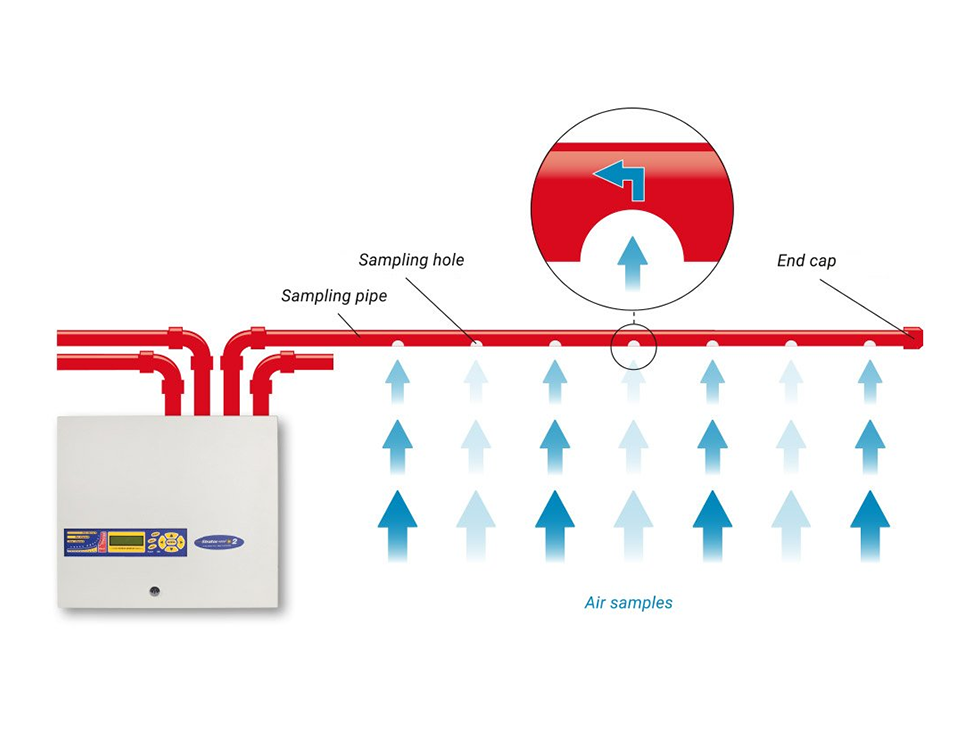

Active air sampling systems can have 1, 2, or 4 channels depending on the brand and model. 20-25 mm ABS pipes are installed in each channel. Maximum pipe length and number of holes varies according to brands and models. For example, for a 4 channel system, the max. pipe length is 200 meters and 4x50m or 2x100m or different combinations can be used. Air sampling systems are made by applying the following steps. These steps may differ according to brands.

- The ideal orifice diameter in pipes is determined by the manufacturer’s modeling software

- An average of 25 orifices are accepted in a pipe

- The arrival time of the air from the last hole to the detector can be up to 120 sec.

- Exhaust must not be exhausted into the detection environment

- Each hole on the air sampling pipes is considered as a smoke detector and pipe layouts are made accordingly

- Before the application, hole diameters should be calculated by the modeling program obtained from the manufacturer, and air flow velocities should be checked

Why Use an Active Air Intake or Air Sampling Fire Detection System?

- Earliest detection for business continuity

- Prevention of unnecessary gas discharges

- The need for extra time for a safe evacuation

- Difficulty detecting smoke

- Challenging factors such as dust and humidity

- The need for aesthetic and unobtrusive perception

- Areas with difficult access to detectors for maintenance

Air sampling detection systems are used for reasons such as the above.

Areas of Use

- Telecommunication facilities

- Computer rooms

- Production facilities

- Subway stations

- Theaters and Cinemas

- Shopping Centers

- Public Buildings

- Clean rooms

- Industrial Warehouses

- Aircraft hangars

- Atriums

- Cold storages

- Underground tunnels